MSX

MSX Critical Minerals and Metals Processing Technology

Global supply challenges mean the world urgently needs to focus on the efficient recovery and re-use of critical minerals and metals.

Processing technologies and systems not only need to have attractive returns on investment (ROI) but also be efficient in the use of resources, generating less emissions including CO2, while supporting communities in which they operate. Hence, the choice of critical minerals recovery is mission critical.

With our simple, elegant Membrane Solvent Extraction (MSX) processing technology that yields best-in-class recovery rates of 95% or more and purity of 99%, Momentum is turning problematic critical minerals and metals waste into high quality products delivering attractive ROIs, eliminating unnecessary costs, and reducing emissions to secure the global supply chain of critical minerals.

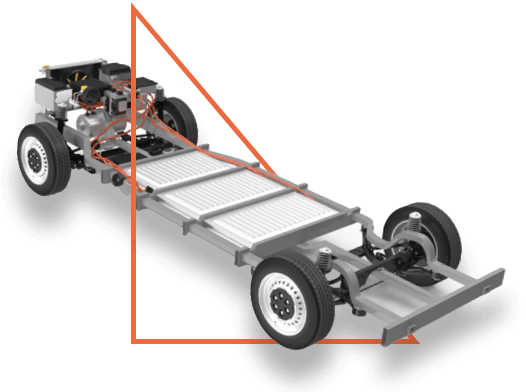

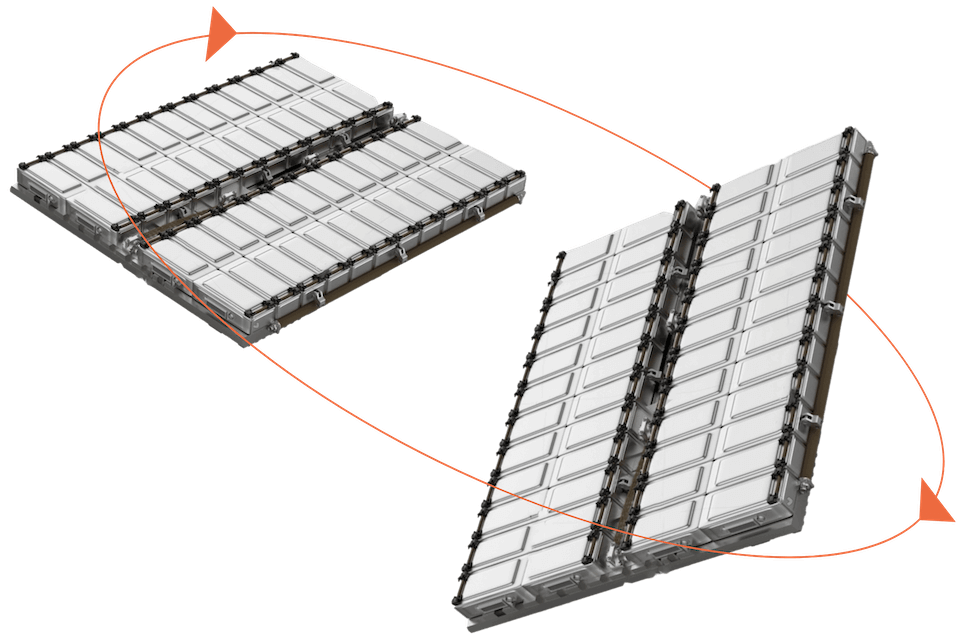

Momentum’s modular offerings enable a distributed approach to processing used lithium-ion energy storage devices and other critical minerals containing waste. Customers and communities, regardless of their size, can install the proprietary MSX systems that make the process more efficient, affordable, and advance energy security by eliminating dependence on non-local supply.

MSX exceeds processing methodologies pyrometallurgy, direct recycling, and hydrometallurgy, yielding the highest purity and end-compound flexibility while generating the lowest harmful emissions.

Our modular system design places the processing facility, system, or plant in close physical proximity to the producer of the critical minerals waste including battery waste, thereby reducing the financial and environmental impact from shipping (as high as 60% of battery recycling costs) of critical minerals across great distances.

At the center of Momentum Technologies’ current solution offerings are the proprietary MSX-C stages. Each MSX-C stage selectively capture and/or remove desired and/or undesired compounds. Optimized process design ensures high throughput, efficient use of reagents and utilities, and high selectivity from each MSX stage.

Each MSX stage can be considered as a base foundation block which can be replicated block-by-block in series to process materials at a larger scale.

The entire proprietary process, covering the MSX-PREX, MSX-C, and MSX-POSTX blocks can be packaged to adapt to the scale and type of raw material that needs to be processed.

The MSX-PREX pre-treatment block consists of a series of equipment whose combined unit operations include solid powder handling, dissolution, and precipitation under moderate temperature and pressure conditions. The main goal of this block is to transform the raw material into the desired phase and remove easy to remove contaminants.

The MSX-C (“C” = core) block receives the treated raw material in the required phase and composition and sequentially separates desired and undesired materials including Iron, Copper, Cobalt, Nickel, and Lithium.

The MSX-POSTX post-treatment block converts the mostly separated material mixture into desired end phase ready for packaging and sale.

Momentum’s business model flexibility, including BOOM and turnkey technology plant solutions, offers clients and their stakeholders options to deliver the highest returns on investment, adaptable to the desired feed stock and processing capacities.

SOLUTION 1

MSX Core 100

SOLUTION 2

MSX 1000T BMod

SOLUTION 3

MSX 500T CMod

MSX System

Business Models

Momentum offers flexible business models to suit your stakeholders’ needs in terms of scale, footprint, raw materials, balance sheets, and capability including:

- Build Own Operate and Manage (BOOM)

- Technology Transfer Model

- Licensing and Royalties Model

The BOOM model allows governments to leverage private sector expertise and funding to develop and maintain critical infrastructure assets without solely relying on public funds. In return, the private consortium earns revenue through user fees, tolls, or other revenue-sharing mechanisms during the concession period.

The Technology Transfer model enables the R&D entity to transfer the technology to other companies or partners via licensing agreements, joint ventures, strategic partnerships, or outright sale of the technology.

Licensing and Royalties agreements outline the terms and conditions under which the technology can be used, the scope of its application, and the financial arrangements between the parties.

The BOOM model:

The private consortium takes on the responsibility to design and construct the infrastructure project, but it may also receive funding or support from the government or other stakeholders.

Once the project is completed, the private consortium becomes the owner of the infrastructure asset. This ownership gives the consortium the right to operate and manage the facility for a defined period.

The private entity runs the infrastructure facility efficiently and ensures its functionality and maintenance.

The private consortium handles the management aspects of the project, which may involve financial management, customer service, regulatory compliance, and other administrative duties to ensure the smooth functioning of the facility.